Purpose

-

Why does Stablex exist?

Stablex stems from a call for tenders issued by the Ministry of the Environment (then MENVIQ in the 70s) when Quebec needed to treat and dispose of industrial waste and contaminated soil. The technology proposed by the CRIQ (Centre de Recherche Industrielle du Québec) caught the attention of the Quebec government. And so, in 1983, the company was born in Blainville.

Today, the need for industrial and contaminated waste treatment and disposal is as great as ever. Few North American companies offer stabilization and disposal services for inorganic industrial waste, making Stablex’s activities essential to ensure proper handling of hazardous materials and contaminated soils.

-

Why is it necessary to have a facility like Stablex in Quebec?

A facility like Stablex is often the ultimate and only disposal solution for local companies, enabling them to comply with the regulations that govern residual hazardous materials and contaminated soils. Stablex was created in the 1980s to support the implementation of these regulations, which aimed to raise environmental standards.

For example, in Quebec, municipal incinerators (to dispose of their ash and spent lime), industrial cleaning companies, companies involved in land remediation (past environmental problems), all transfer centers (which serve eco centres and hundreds of small generators of residual hazardous materials across the province), as well as battery recyclers, are Stablex customers. Stablex’s clientele also includes well-established Quebec industries such as metallurgy (steelworks, foundries, galvanizing, refining, aluminum) and aeronautics, that depend on the Stablex treatment center.

If the Stablex site did not exist, provincial requirements would force all these generators of residual hazardous materials and contaminated soils to find other, more distant, more costly, or less environmentally safe final disposal solutions to dispose of their residues.

The significant and sustained increase in demand for Stablex’s services indicates the importance of continuing to offer these environmental services, while at the same time advocating for the application of the 3RV principle (reduction at source, reuse, recycling, and recovery). At present, and in the years to come, Stablex is/will be called upon to assist in the carrying out of certain major works (e.g., Turcot interchange and REM) and to support government decontamination programs (e.g., orphan sites), as well as to improve environmental practices for several industrial companies.

-

Why Blainville?

At the time of the Ministry of the Environment’s call for tenders for a technology that would allow the safe disposal of hazardous materials, the location of the future site was a central component. It had to be close to downtown Montreal. The North Shore was quickly targeted because of its ideal geology for a placement site, namely its thick layer of clay derived from the ancient Champlain Sea. Several locations were assessed in the region, and finally, the City of Blainville itself proposed land to host the site and the technology.

For all these reasons, Blainville remains to this day a prime location for an organization like Stablex, both for its plant and its landfill cells. Stablex makes a point of being a full-fledged member of the community, both financially and socially (e.g.: donations and sponsorships, active participation in community events, etc.).

Process

-

What is the stabilization and solidification process used by Stablex?

The process used at Stablex allows contaminants to be rendered insoluble and materials to be rendered immobile by being placed in the safe environment of a placement cell.

Stabilization: incoming materials are mixed with stabilizing agents, such as chemical reagents and cementitious binders. These agents are chosen according to the characteristics of the materials to be processed and may be other incoming materials. Chemistry at work! These chemical treatments aim to eliminate hazardous materials by transforming them into non-hazardous ones, to neutralize their corrosiveness, or to reduce the toxicity of contaminants present in the materials by transforming them into their less hazardous forms.

Solidification: Next, the mixture gradually solidifies. This means that it transforms into a solid substance that encapsulates the materials and prevents them from dispersing into the environment. It takes some time to harden at the placement site. Stablex trucks can drive to the edge of the “cured” stablex after about 3 weeks.

-

Why does Stablex treat 100% of the contaminated materials and soils it receives?

The treatment of all materials and soils received distinguishes Stablex from other alternatives that rely more on direct disposal. The treatment stage renders contaminants insoluble and materials immobile before they are disposed of at a placement site. This process is known as “stabilization-solidification”. The final product becomes inert from an environmental point of view, ensuring a safe placement site and preventing residual hazardous materials and contaminated soils from impacting the environment.

-

How does Stablex verify that the process has achieved its objectives once the product has been placed on-site?

There are several control and follow-up measures to ensure that the stabilization-solidification process has worked properly and that the placement site is environmentally safe. The main measures are as follows:

- Each batch of stablex (the name used for the materials undergoing the stabilization-solidification process) undergoes tests to verify its physical and chemical properties before it leaves the plant for the placement site. These properties must comply with strict criteria, periodically checked by authorities. Samples are also preserved to test the evolution of each batch of stablex over time.

- At the site, all rain water that falls into the active placement cells is collected and treated per current standards and regulations.

- Samples are taken periodically to assess groundwater quality, by monitoring the wells near past and present placement cells.

Type and Origins of Materials Received

-

What types of materials does Stablex receive?

Each year, Stablex serves around 600 different companies. The Stablex site is already the final disposal site for many of these manufacturers, who use technological and environmental solutions in their processes (e.g.: contaminated water treatment, air purification, metal recyclers, etc.), but who, at the end of the day, still find themselves with an ultimate residue to manage.

Stablex, therefore, accepts materials such as:

- Contaminated soil

- Furnace dust

- Spent corrosive cleaners

- Electrical and electronic process residues

- Filters and filter residues

- Sludge

- Asbestos

- Debris

- Batteries

- Etc.

Stablex does not receive flammable, explosive, or nuclear products.

-

Why does Stablex receive waste from outside Quebec, like neighbouring Canadian provinces and the United States?

Stablex works with Canadian and U.S. companies to provide safe industrial waste disposal services. Stablex has committed to accepting a limited quantity of materials from the United States. The Quebec government has also established limits and mechanisms to ensure that priority is given to Quebec companies and industries. Government authorizations granted to Stablex govern the quantities of materials that can be received, as well as their admissibility.

Finally, it is important to understand that cross-border movements of hazardous residual materials are also governed by federal regulations and a strict permit process that meets the requirements of international agreements between Canada and the United States.

-

How can Stablex ensure the safety of its operations when hosting hazardous materials on its site?

The Stablex team has put in place several measures to ensure the safety of its employees and neighbours. These include:

- Each container received is sampled. They are all analyzed in our in-house laboratory.

- Certain areas are segregated according to the type of residue processed, to avoid incompatibilities between the materials received.

- A watertight barrier and a rain recovery system are installed all around the plant.

- Rigorous preventive maintenance and equipment inspection.

- Continuous monitoring using automated systems.

- A management system for all changes at the site is in place to ensure constant safety.

- All staff and subcontractors are trained to perform their tasks safely.

- The emergency response plan is reviewed, updated, and tested annually.

- The health and safety team is ready to intervene at any time, members of the emergency response brigade are trained regularly, and state-of-the-art equipment is at their disposal.

- An established and fruitful collaboration with the Blainville Fire Department ensures that protocols are established, revised, and tested through joint simulations.

In short, control measures from hazardous material reception to placement, engineering and design of the treatment center and placement cells, and training and collaboration within the Stablex team and with local and regional stakeholders are all important factors in ensuring public safety.

Cell 6 Project

-

Why did you choose the current project site?

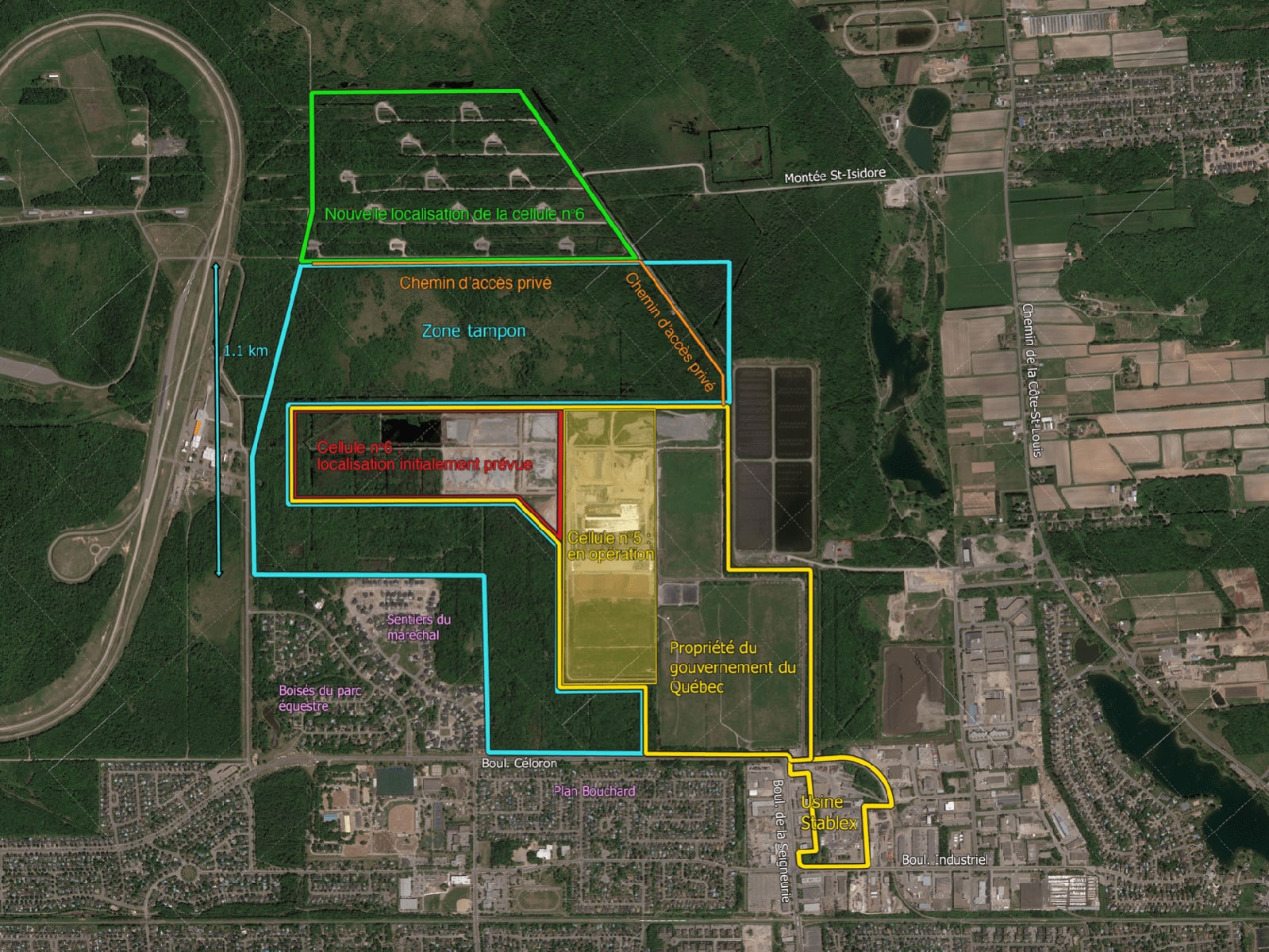

Consultations with the neighbourhood led to the decision to relocate Cell 6. Indeed, during a process designed to promote better cohabitation, it was put forward that moving Cell 6 further away from residences would be beneficial to maintaining the quality of life of nearby residents. By moving the site away to a radius of 1.1 km, potential irritants associated with to operations, such as noise and odours, would be considerably reduced. This distance will provide a more effective protection for people living nearby, compared to the 300-meter buffer zone originally planned for the site.

From an environmental and operational point of view, the site had to be located close to the treatment center, yet away from residential areas. In developing the project for the redevelopment of Cell 6, several advantages were identified and derived from the chosen location:

- Remain close to the Stablex processing center, which reduces the need for transportation to store stabilized materials, and thus minimizes additional GHG emissions and costs.

- Remain in the area with favourable geological conditions for this type of installation (initially identified in the site search when Stablex was set up in the 1980s), the important clay layer being a determining factor in the design of Stablex cells.

- Use of an already disturbed and industrially zoned site.

- Reduce the project’s impacts to natural areas, due to the partially existing access road and the smaller encroachment of the proposed site compared with the one that was initially planned.

The choice of the proposed site is, therefore, the fruit of collaboration with the community, and was determined through a multi-criteria analysis considering social, environmental, and economic aspects.

-

Why plan a 40-year project?

Stablex has planned its project over a 40-year horizon, per the current rate of operations and incoming material. The aim is therefore to optimize the available space to offer a long-term solution for the company’s customers while minimizing the project’s impacts to the environment and the population. In the event of a slowdown in demand, there will still be ultimate residues, so the available space can be used over a longer period, ensuring the continuation of Stablex’s essential services.

Corporate Governance and Direction

-

Why is Stablex owned by an American company?

Stablex’s ownership has changed over the years, but the local team has been fairly stable over the last 40 years. Stablex’s Managing Director has been with the organization since 1999, and the Stablex team has an average of 11 years of seniority.

The company has been owned by an American company since 2010. The change of ownership has resulted in no operational changes or changes in the source of materials received. Stablex remains governed by Quebec and Canadian regulations and authorizations.

Stablex was acquired by Republic Services in 2022. This acquisition was made possible in part because of an alignment of corporate values and orientations between the new owner and Stablex. There are many advantages to being part of the Republic Services family, including green investments, shared expertise and resources, long-term stability, etc.

-

What role does Republic Services play in Stablex’s operations?

As an owner, Republic Services plays a key role in the administration of Stablex, including strategic control, financial management, sharing of knowledge and skills, and coordination and harmonization of activities with the company’s values.

The merger of the two companies has enabled the sharing of knowledge in waste management, as well as securing funding for facility maintenance and future green economy projects at the Stablex facility.

-

How does Stablex contribute to the 3RV principle (reduction at source, reuse, recycling and recovery)?

Since the beginning of its operations, Stablex has been recovering incoming materials with chemical characteristics that are useful for the stabilization of other materials. For some years now, Stablex has had the vision to develop environmental solutions to transform residual hazardous materials into value-added products. Among these projects, the transformation of ammonia-containing residues into fertilizer has already been authorized. Others are currently under development, such as the screening and segregation of rocks in incoming soils and their cleaning for reuse. Another project is the production of hypochlorite (a disinfectant and bleaching agent) from chlorinated residues. The materials thus diverted from the landfill site have a useful second life!